Free Shipping on orders over R3,999. T's&C's Apply.

Why Choose a Hot Water High Pressure Washer

If you have been looking for high pressure cleaners, you will realize there are several options to choose from: cold water, hot water, and petrol pressure washers. However, if you are looking for an industrial grade high pressure cleaner that offers a deeper cleaning capability and high efficiency, then a hot water high pressure cleaner is worth the consideration.

We will go through the advantages and reasons why a hot water high pressure cleaner is the perfect choice for you.

Hot water cleans more efficiently

A clear advantage of hot water high pressure cleaners is that they can increase the water temperatures to as much as 155°C in the steam stage, this means it can increase the cleaning power and also has a disinfecting effect. Hot water aids in the breaking down of grease and oils, making it an ideal choice for industrial applications or situations where these types of stains are prevalent in some areas such as food processing plants where it can easily break down proteins and fat.

Not only is it great for removing greases and oils but also achieves a high standard of hygiene. They are also useful for cleaning and disinfecting areas such as walls, ceilings and floors and for eliminating bacteria, germs and viruses. This is because hot water has a significant contribution when eliminating disease carying germs. Thanks to the combination of high pressure cleaners and hot water of up to 95°C, a large amount of contamination can be reduced. This hot water is often sufficient and requires no chemicals to meet hygiene requirements.

How hot water high pressure cleaners work

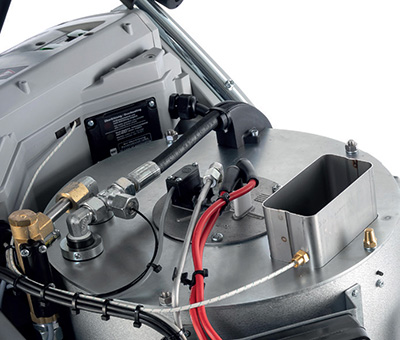

The Kranzle hot water high pressure cleaner combines many technical innovations that provide the highest performance, reliability, safety and operating convenience in daily use. The adjustable burner capacity by way of temperature or performance percentage in accordance with specifications is one of the technical highlights of the Kranzle hot water series. Visual flame monitoring, operating hours meter and comprehensive safety measures transform the machines into dependable, environment-friendly, clean and silent products.

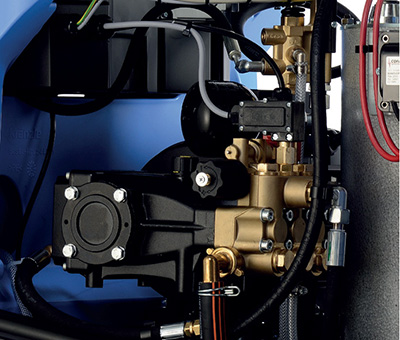

The Kranzle Electra is an electrically heated unit that heats the water after the pump, preventing cavitation as this is a problem found in most electrically heated high pressure cleaners that heat the water before the pump. Using electrical elements to heat the water has shown considerable savings in cost to heat the water and up to 8% savings on maintenance costs compared to diesel heated systems.

The Kranzle Therm Diesel heated units use a diesel burner to heat the water passing through the coil.

Digital control panel

With the digital temperature control, the water temperature and the heat output can be measured exactly and can be controlled via two operating modes. This gives the abillity to work precisely even with partial water quantities and low temperatures.

Once the correct percentage is established, mode 2 has an advantage over mode 1 in that temperature can be accurately kept at + or -1°C. This can even be achieved with reduced water quantities and at low temperatures, ideal for example, when washing livestock. All the settings are saved in the thermostat's memory and are applied when the machine is next used.

Operation mode 1: Thermostat regulation

The target temperature in °C can be adjusted by pressing the buttons (+ -). The thermostat measures the water temperature at the heating coil outlet and causes the burner to either switch on or off in accordance with the operators settings. The outlet water temperature is displayed in °C.

Operation mode 2: Burner output

Press buttons (+ -) to adjust the amount of time the burner will operate as a percentage. The burner will be switched on and off in accordance with this value. The actual water temperature is measured at the heating coil outlet and displayed in °C. The temperature can be raised by increasing the percentage of the time that the burner is operating, or lowered by reducing the percentage.

Optical flame monitoring and thermal overload protection

Electronic monitoring of combustion: Kranzle therm devices have a photocell to monitor the burner flame. This ensures safe operation at all times, even if the user is not near. Additionally, an overheating protection sensor measures the temperate at the exhaust; switching off heating automatically if more thank 260°C is detected.

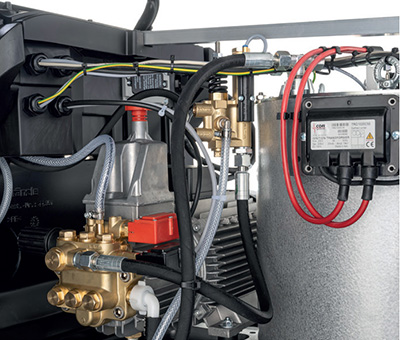

Safety devices

Protection and safety is high priority: features such as a safety valve, flow monitors, optical flame monitoring, overcurrent release, pressure switch and low fuel cut-off switch ensure for absolute safe operation. Pressure control valve: for continuos control of water quantity and pressure and pressureless bypass operation. Safety valve: protects machine against unallowed excessive pressure.

Total-stop system with delayed motor shutdown

Energy consumption is reduced, longer life: when closing the high pressure gun the motor switches off automatically, relieves the high pressure pump and drive and reduces noise. Thanks to a small time delay when switching off machines means that with very short work breaks the full working pressure is immediately restored.

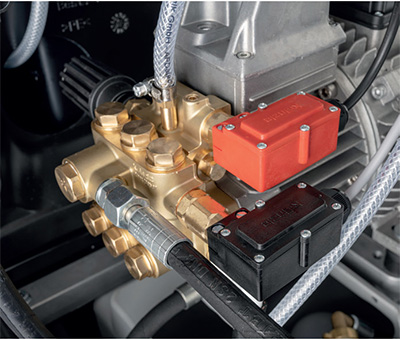

Innovative in-line RP pump

Proven technology convincingly enhanced: a crankshaft moves the plungers in line via connecting rods the in-line pump. This special design enables even greater water flow with significantly higher washing effect than conevntional pumps and ensures impressive properties:

- Power transmission as with a car engine

- Extremely long service life

- Integrated unloader valce

- Total-stop system

Advantages of hot water high pressure cleaners

- Heat accelerates cleaning process

- More effective breaking up of oil and grease

- Labour cost savings

- Shorter drying times

- Use less cleaning agent

- Germ reducing effect

- Cost effectiveness