Free Shipping on orders over R3,999. T's&C's Apply.

Since Kränzle's introduction to South Africa in 1989, Kränzle has built a reputation as a reliable partner that supplies high-quality high pressure cleaning equipment backed by excellent service. Kränzle Germany is a world leader in the design and manufacture of high pressure cleaning equipment and we are proud to be the South African distributor of Kränzle products.

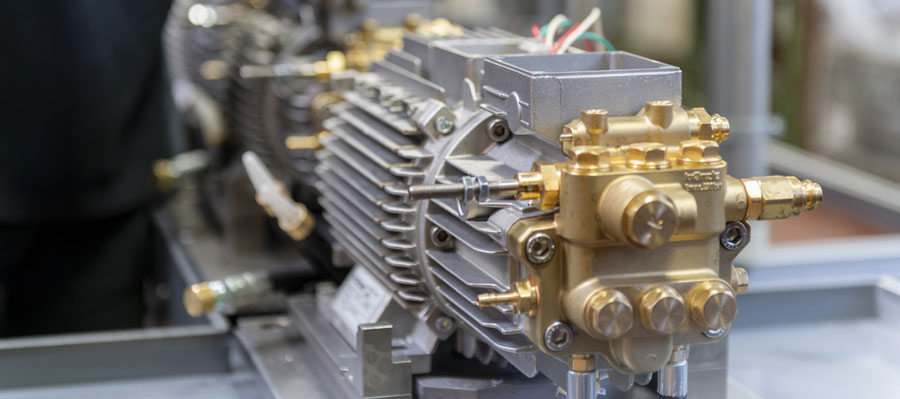

The success of Kränzle products is greatly due to the importance attached to the research and development at both Kränzle Germany and our local facility in Cape Town. The heart of any high pressure cleaner is the high pressure pump, and Kränzle pumps are made completely of forged brass, ensuring top quality and long service life.

With more than 34 years of experience, Kränzle South Africa has evolved into a considerable partner in the supply of pressure washers to the professional and industrial sectors. Our Cape Town factory gives us the ability to manufacture custom-made systems to meet specific needs set out by customers. This includes mounting pumps into cabinets or frames, installing centralized systems, and practically any other high pressure application.

Kränzle products are known for their quality, reliability, and performance. In saying this, we are confident that we are able to supply you with the highest quality high pressure cleaning equipment in South Africa.

Special Brass Pump Head

The heart of every Kränzle high pressure cleaner is the solid pump head made of forged special brass. Both the proven axial pump, which has been installed for decades, and the in-line RP pump introduced in 2018 for higher flushing performance, guarantee a longer service life due to low-wear components.

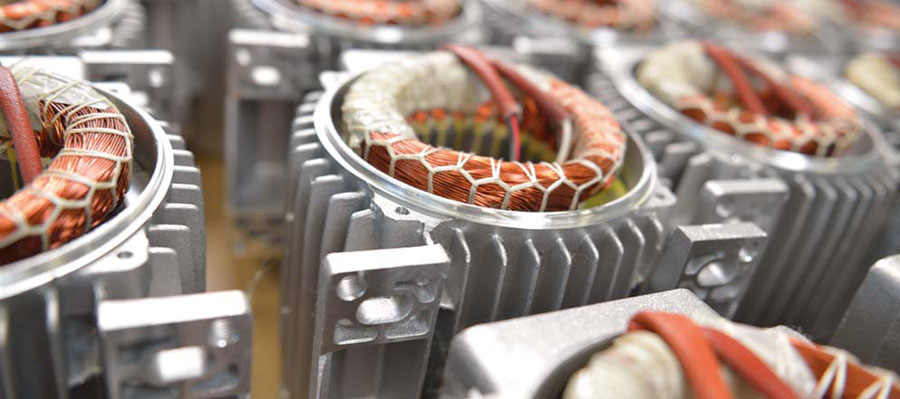

Slow Running Electric Motor

This features ensure a machine that is economical, quiet and durable: The particularly powerful high pressure cleaners for continuous operation are equipped with a 4-pole electric motor. The low motor-speed of 1400 rpm reduces the starting current with the main benefit being less wear-and-tear with big saving on maintenance costs.

Adjustable Pressure Control

With all high-pressure cleaners (except the K1050-series), the working pressure and water quantity can be individually adjusted to the respective application.

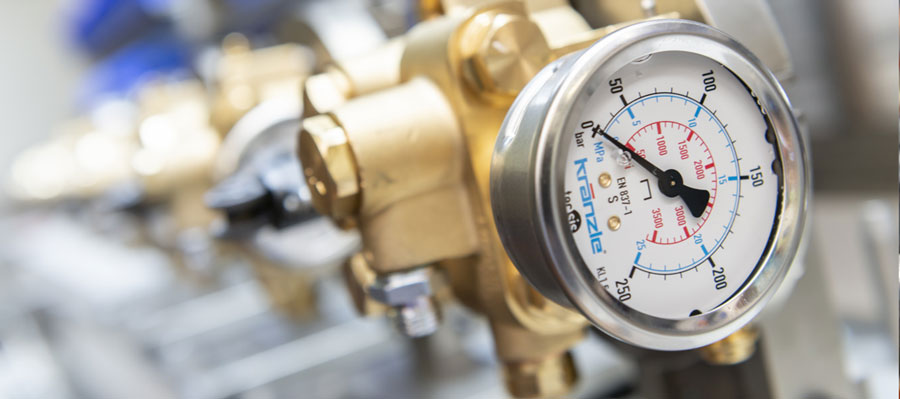

Stainless Steel Pressure Gauge

The large stainless steel pressure gauge provides a clear reading of the set working pressure. It contains a glycerine liquid that dampens possible fluctuations of the pointer.

Stainless Steel Pistons

All high-pressure cleaners are equipped with ceramic coated stainless steel plungers. The favourable features of stainless steel plungers (excellent thermal conductivity), are combined with the positive characteristics of a hard ceramic coating (extremely low-wear surface) This serves to considerably increase the service life of our systems.

Dry-run Safety

All high-pressure cleaners are equipped with a fabric sleeve and a Teflon graphite backing ring on each plunger. The excellent lubricating properties of Teflon graphite serve to reduce both the friction and temperature inside the pump. For this reason, Kränzle pumps can be run without water for quite some period without suffering any damage = Dry-run safety. A water cushion between the high-pressure seals on the plungers prevents any sucked in air from reaching the pump chamber. This considerably increases the service life of the plungers and pump.

Roto-Moulded Chassis

The practically indestructible plastic housing gives the pressure washer additional stability. Motor and pump are well protected in the frame, securely shielded from external influences. The robust chassis ensures easy transport and high stability.

Totalstop System | Safety Shutdown

Energy consumption is reduced, service life up: when closing off the high pressure gun, the motor switches off automatically, relieves the high-pressure pump and drive and reduces the noise level. If the high-pressure cleaner is accidentally not switched off, after 20 minutes it automatically goes into the safety shutdown by deactivating it.

Hose Reel | Twist Stop Screw Connection

Models with hose reels allow for neat storage of the high pressure hose. The twist stop screw connection also prevents the hose from twisting during work and guarantees an undisturbed cleaning process.

Water Box

A float in a water box switches off the motor pump when a certain water level is reached and prevents pump damage in the event of lack of water.