Free Shipping on orders over R3,999. T's&C's Apply.

CUSTOM-MADE HIGH PRESSURE WASHER SYSTEMS

One unique benefit of doing business with Kränzle South Africa is that we have our own in-house manufacturing facility in Cape Town. Here we assemble and manufacture our local high pressure cleaner machine options and customer-specific cleaning systems all centred around high pressure cleaning and the heating of water – this page gives you an idea of the broad range of different systems and projects we have completed to solve customer applications.

Please note: These custom-made systems are not manufactured by Kränzle Germany but in our local factory in Cape Town. In the interest of offering our clients personalized solutions, however, we use Genuine Kränzle pumps and components to build these systems.

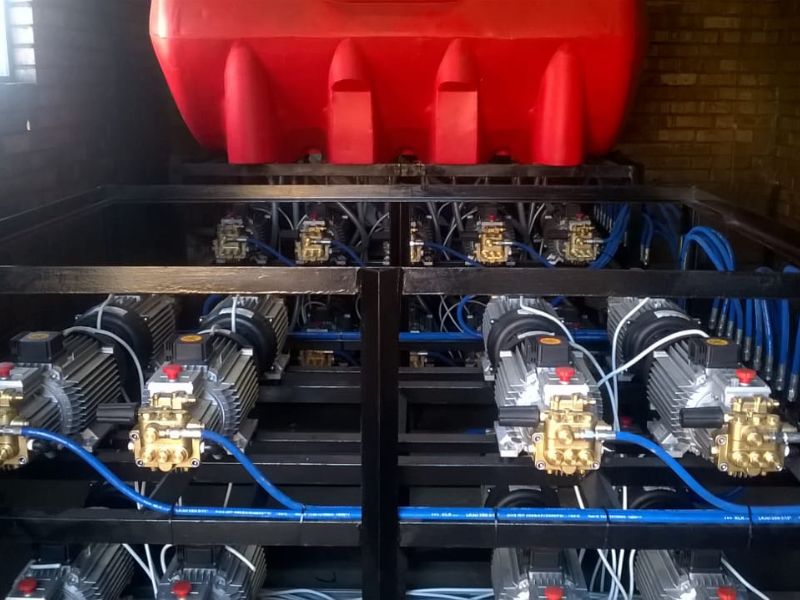

MULTI-PUMP HIGH PRESSURE SYSTEMS

Kränzle South Africa is the leader in multi-pump high-pressure cleaner systems, whatever requirements our customers require we are able to build the system to your specifications and needs.

Our custom-made multi-pump systems bring together the highest quality "Made in Germany" high pressure pumps along with personalization. Built on stainless steel frames or cabinets, for the longevity and durability of the systems.

DOUBLE BARREL WINE CLEANING SYSTEM

There are wine cellars with high-volume barrel cleaning requirements and these have preferred using the Kränzle Double Barrel Cleaner system where cleaning is done with barrels on the cradle.

Equipped with two cleaning bays, the unit cleans two barrels mounted on one cradle during which a forklift operator can off-load and load the next cradle with barrels onto the other cleaning bay.

The Kränzle Double Barrel Cleaning System is currently used in a number of South African wine cellars with the largest cellar cleaning handling up to 24000 barrels per year.

Normally supplied with two Kränzle Electra 48kW high pressure cleaners, it is equipped with an operator control panel, adjustable wash-period timers, pneumatic lifting of the cradles as well and rollers to allow rolling of the barrels without making or causing damage.

This unit is an indication and example of what we have made and can be adapted to include other processes such as steaming, cool-down, hot- and -cold wash, barrel hydration etc...

We will gladly visit to your cellar to discuss your requirements.

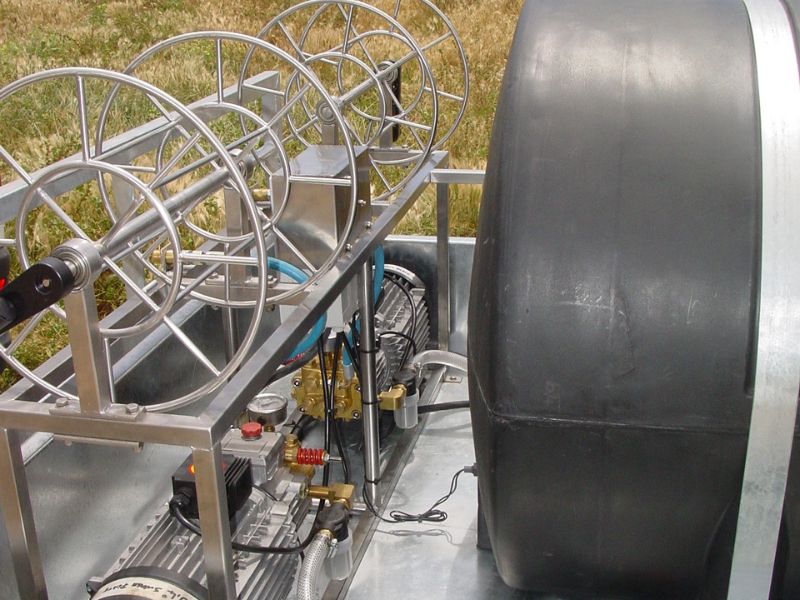

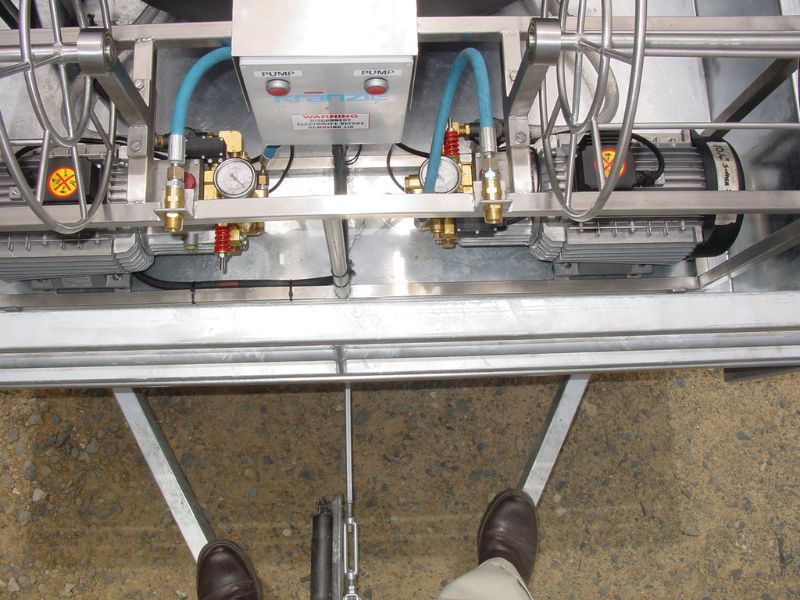

TRAILER MOUNTED HIGH PRESSURE CLEANERS

The Kranzle Trailer Mounted High Pressure Washer is the ideal system for cleaning where a water source is not readily available. We manufacture these industrial systems according to your specifications and needs. Installed with a water tank and industrial high pressure cleaner motor and pumps.

This specific system was built for the application of poultry cleaning and foaming systems for the foaming of poultry broiler houses where longer hoses are required to facilitate broiler house cleaning.

DRIVE-THROUGH CARWASH

Drive-through car wash installation built with drying blowers, designed to clean in excess of 200 cars per day.

This is normally designed specific to your requirements as this is just an indication of what can be done.

BIKE WASH STATION

Every year we have been involved with the Cape Epic and Wines2Whales cycle races by supplying and supporting the bike washing equipment. These units, mounted in stainless steel cabinets, have stood-their-ground in the rough environment, especially with the handling and moving between sites, under sometimes very difficult conditions. They have proven to be extremely reliable with minimal issues when they have been used to clean the more than 600 mountain bikes daily.

This is a daily job that applies for the full duration of the Cape Epic and the multiple stages of the Wines2Whales between Somerset West and Hermanus.

CAR WASH MULTI-PUMP PRESSURE WASHER

This four-pump Carwash cabinet was manufactured for a car wash, connected to swivel booms in the car wash bay area. The Customer requested a high pressure pump system that could be placed in a secure and separate pump room also to minimise the noise factor.

The additional high pressure pump shown, was supplied together with a "Dosatron" for accurate chemical dosing, to apply the foam through the double booms fitted with guns and foaming lances.

GENERATOR FUEL TANK WARMER

During the Winter months in the Maluti mountains, the electricity supply to the Telecommunications towers may get interrupted by snow and extreme weather, and a diesel generator is in place to automatically supply power in the event of an outage. The temperatures have usually dropped below freezing and the temperature of the diesel in the generator was too cold, making it difficult for the generator to ignite.

The Tank warmer equipped with a heat exchanger plate was developed and the latter installed under the diesel tank of the generator. This was set to automatically switch on when the outside temperature reached a certain point. This activated the unit and circulated the glycol through the elements and the exchanger plate, gradually heating up to a point to warm the diesel in the tank and eliminated the problem of the "too-cold diesel". Problem solved!!