Free Shipping on orders over R3,999. T's&C's Apply.

The High Pressure Cleaner Keeps Switching On and Off After Closing High Pressure Gun

Problem:

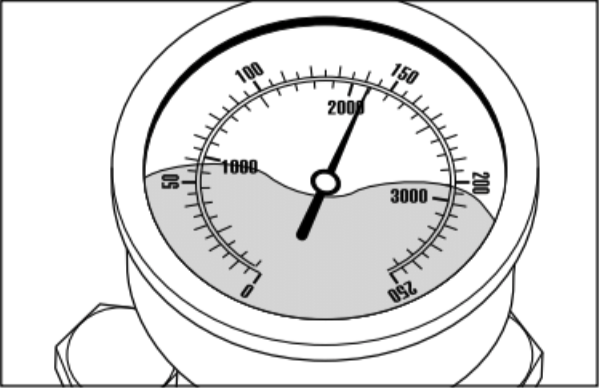

The Kränzle high pressure cleaner is turning on and off after cleaning and closing the high pressure gun, and the high pressure gauge continues to show full pressure.

Possible Cause No. 1: Leakage

After closing the high pressure gun with the safety catch, the high pressure cleaner should shut down and the stainless steel pressure gauge must show "0" bar. If the machine shuts down and the stainless steel pressure gauge continuously shows full pressure, this could be due to four possible leakage areas:

- Leakage at the high pressure pump

- At the pressure switch

- High pressure hose

- High pressure gun

How to fix:

If you are experiencing this issue, follow the procedure:

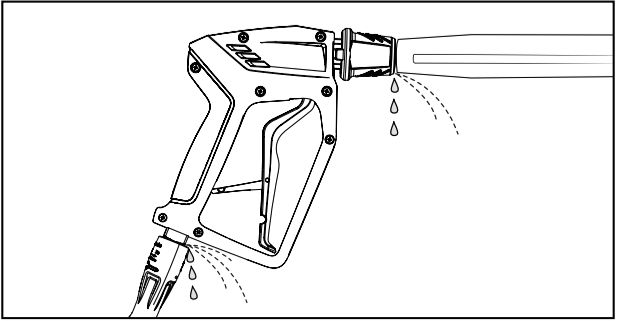

Check your connections from the high pressure cleaner to the high pressure hose and from the high pressure hose to the safety trigger gun and also the connection between the lance and safety trigger gun for tightness and any leaking water.

Switch off the high pressure cleaner and remove it from the power supply.

Shortly press the trigger of the high pressure gun to decrease the pressure in the system.

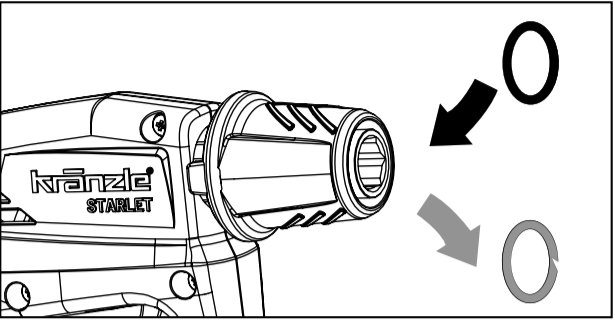

Remove the high pressure hose from the trigger gun and lance, and check the O-rings for any possible damage.

If the O-rings are damaged they will have to be replaced.

Please note: In case of a leakage there is no guarantee for possible consequential damages.

Possible Cause No. 2: The non-return valve is defective

How to fix:

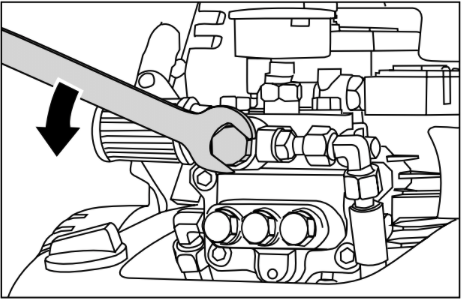

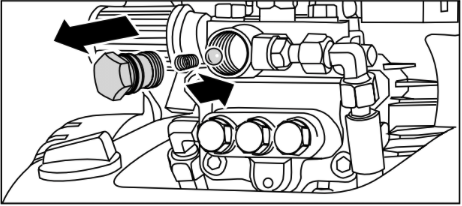

Switch off the high pressure cleaner and unplug from the power supply. Remove the water supply to the machine. Press the trigger gun several times to decrease the pressure. Proceed to unscrew the pump outlet.

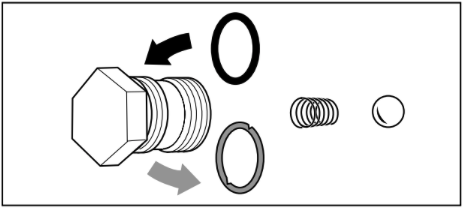

Remove the body and O-ring and check for any soiling or damage. Also, check the seal seat inside of the high pressure pump housing for soiling or damage.

If sealing rings are defective replace all the O-rings at once.

Please note: There is no guarantee if the high pressure pump is damaged by defective O-rings due to air induction or lack of water (cavitation).